Cold rolled rebar model

Cold Rolled Rebar Model: Enhancing Performance and Durability

Abstract:

The Cold Rolled Rebar Model has become an increasingly popular choice for construction projects due to its superior performance and durability. This article aims to provide an in-depth understanding of this model, discussing its benefits, applications, manufacturing process, and advancements in the field. By exploring these aspects, readers will gain valuable insights into the Cold Rolled Rebar Model and its potential to revolutionize the construction industry.

1. Benefits of the Cold Rolled Rebar Model

1.1 Increased Strength and Durability

Cold rolling enhances the strength and durability of rebars, making them more reliable and capable of withstanding higher loads. This model also exhibits superior resistance to corrosion, ensuring long-term durability for various construction projects.

1.2 Enhanced Bonding Properties

The Cold Rolled Rebar Model promotes better bonding with concrete due to its unique surface characteristics. This ensures improved structural performance and prevents the occurrence of cracks or fissures in concrete structures.

1.3 Cost Efficiency

Despite the initial higher cost of cold rolling production techniques, the Cold Rolled Rebar Model offers long-term cost efficiency. Its enhanced durability and reduced maintenance needs result in significant cost savings throughout the lifespan of a construction project.

2. Applications of the Cold Rolled Rebar Model

2.1 Bridge Construction

The Cold Rolled Rebar Model finds extensive use in bridge construction due to its exceptional strength and resistance to environmental factors. Its ability to withstand the stresses associated with heavy traffic and various weather conditions makes it an ideal choice.

2.2 High-Rise Buildings

In the construction of high-rise buildings, the Cold Rolled Rebar Model provides the necessary structural reinforcement to ensure the safety and stability of these structures. Its high tensile strength and superior bonding properties make it a reliable choice for such demanding applications.

2.3 Infrastructure Projects

Infrastructure projects such as tunnels, highways, and railway systems require materials that can withstand heavy loads and harsh environmental conditions. The Cold Rolled Rebar Model proves to be an excellent choice, as it offers exceptional durability and performance in these settings.

3. Manufacturing Process of the Cold Rolled Rebar Model

3.1 Raw Material Selection

The manufacturing process of the Cold Rolled Rebar Model starts with the careful selection of high-quality raw materials. These materials undergo rigorous testing to ensure they meet the required standards in terms of chemical composition, strength, and ductility.

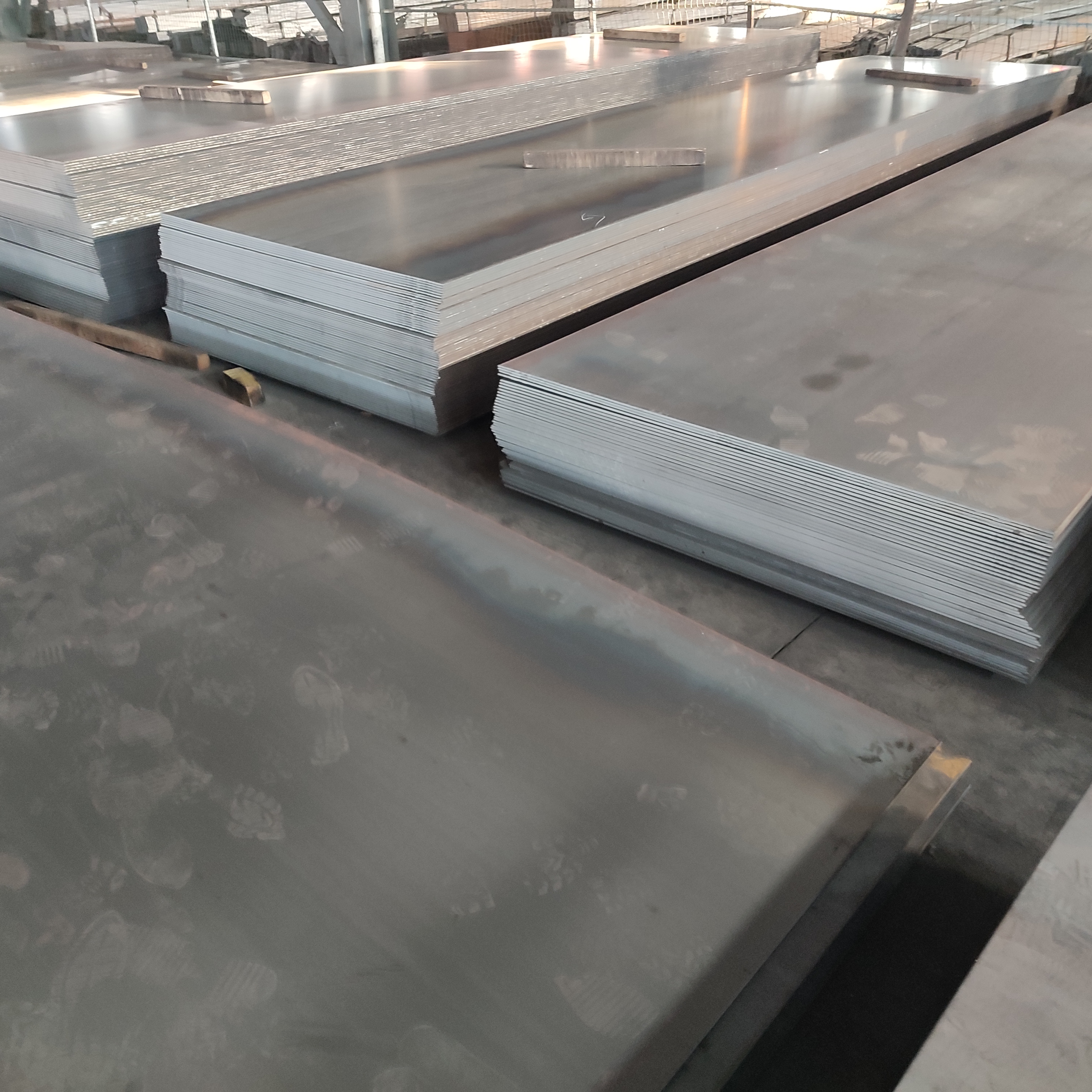

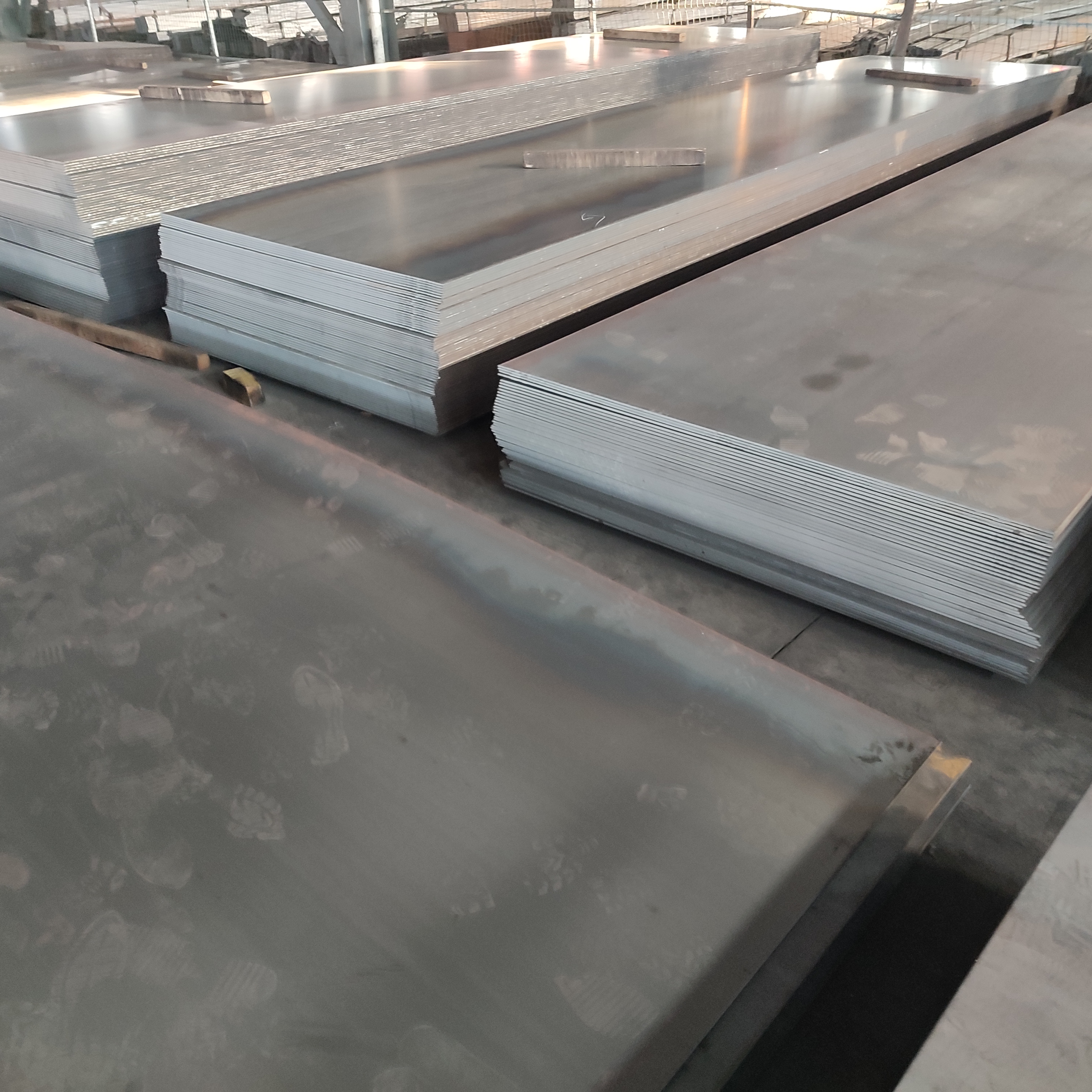

3.2 Cold Rolling Process

The chosen raw materials undergo a cold rolling process, which involves passing them through a series of rollers to reduce their diameter and improve their mechanical properties. This process enhances the strength and surface characteristics of the rebars, resulting in a superior final product.

3.3 Surface Treatment

After cold rolling, the rebars undergo surface treatment to further enhance their durability and resistance to corrosion. This can involve processes such as galvanization or coating, providing an additional layer of protection against environmental elements.

4. Advancements in the Cold Rolled Rebar Model

4.1 Nanostructured Rebars

Researchers are exploring the incorporation of nanotechnology into the Cold Rolled Rebar Model, aiming to further enhance its performance and durability. Nanostructured rebars exhibit superior mechanical properties, improved bonding characteristics, and enhanced resistance to corrosion.

4.2 Composite Rebars

Composite rebars, consisting of a combination of different materials, are gaining attention in the field of construction. By integrating materials with complementary properties, these rebars offer enhanced strength, durability, and flexibility compared to traditional rebars.

4.3 Sustainable Production Techniques

With the increasing focus on sustainability, researchers are developing more environmentally friendly production techniques for the Cold Rolled Rebar Model. Utilizing renewable energy sources and reducing greenhouse gas emissions are key factors in the advancement of sustainable manufacturing processes.

Conclusion:

The Cold Rolled Rebar Model presents numerous advantages in terms of strength, durability, and cost-efficiency. Its applications in bridge construction, high-rise buildings, and infrastructure projects demonstrate its versatility and suitability for various construction needs. The manufacturing process, coupled with advancements in the field, continues to improve the performance and environmental sustainability of this model. As the construction industry evolves, the Cold Rolled Rebar Model is set to play a crucial role in shaping the future of infrastructure development.

Write a comment